- May 20, 2022

- Case Studies

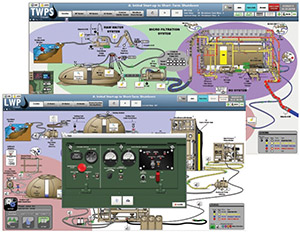

- Upgrading SCADA Software Functionality to its Fullest Potential

The Challenge

Akzo Nobel wanted to improve their operational efficiency. To accomplish that, they needed to upgrade the Klieverik Automatic Dosing Unit (ADU). Before the upgrade, the Klieverik was limited on the amount of storage and could only hold about half of the ingredients needed for the formulas that are made on it. This resulted in most batches being made on and off of the machine, leading to inefficiency and waste. Akzo Nobel’s Research, Development & Innovation (RD&I) department revised over 1,000 formulas to reduce the overall ingredients in the formulas so they could all be placed on the ADU once it was updated. The programmable logic controller (PLC) on the Klieverik did not allow a “fine tuning” dispense feature, so overdosing ingredients in formulas was becoming common and costly. Also, their System Application Products (SAP) system could not be tied into their plant network causing delays in receiving new paint batch recipes from their lab to their plant floor. This was creating additional time and errors because plant operators had to manually transfer information from one system to another.

An upgrade to the Supervisory Control and Data Acquisition (SCADA) software created easy integration to improve efficiency

The Solution

It was important to update the software to reflect the changes that Akzo Nobel wanted with their new Klieverik upgrade. MartinCSI did a complete overhaul on the SCADA software and updated it from a G.E. iFix to an Inductive Automation Ignition software. Changing it to the Ignition software allowed MartinCSI to develop code that would grab files from Akzo Nobel’s SAP software in their lab, and put it into a local SQL database in the plant. By doing this, it eliminated manual data entry in the plant and decreased human error with the updated and improved formulas. With additional tanks and drum stations being incorporated into this upgrade, MartinCSI also created new SCADA screens and PLC functions. The new PLC code and programming gave Akzo Nobel the capability to automatically dispense all ingredients directly from storage tanks to the Klieverik- something they were never able to do before. This also gave Akzo Nobel the fine tuning feature they needed to dispense the right ingredients and help eliminate overdosing. Additionally, once MartinCSI completed all the upgrades for the Klieverik ADU, they provided training to plant operators on the SCADA system and a training manual was developed as a future resource

The Results

- Akzo Nobel increased the amount of batches made on the Klieverik by 114%.

- The Klieverik ADU is fully automatic with no manual tasks required.

- With fine tuning of dosing, overdosing has been eliminated.

- Batch scheduling, inventory management and recipe management are now integrated with the new SCADA system.

- The ROI was less than one year.